Nucycl® is a fiber made from cotton textile waste, offering a sustainable alternative to traditional materials like cotton and polyester. The technology converts textile waste into new engineered fibers that can be recycled repeatedly. Evrnu uses cotton-rich waste sourced from recyclers, brands, and retailers to create Nucycl® lyocell fiber, which works as well as new fibers. This innovative technology helps tackle the problem of textile waste by recycling old clothing into high-quality fibers, promoting a closed-loop system in the textile industry.

NuCycl transforms textile waste into high-quality, regenerative lyocell fibers, offering exceptional performance and significant environmental benefits compared to traditional virgin fibers. Nucycl technology reuses old materials like worn clothing and fabric scraps to extract raw cellulose for making new fibers and yarns.

The process starts with sorting materials by fiber type, followed by removing trims and accessories. The fabric is then shredded and turned into a liquid, with contaminants cleaned out. This purified pulp is used to create r-lyocell fiber, which can be designed for specific features such as durability, stretch, and moisture absorption. The resulting fiber can be woven or knitted and is as strong, or stronger, as alternatives like cotton and polyester. There are two types: 100% Nucycl, made entirely from cotton textile waste, and 31% Nucycl, which contains 31% cotton and 69% wood pulp.

Key characteristics of this fiber include its strength, which is higher than that of rayon, cotton, or polyester. It feels soft against the skin and is breathable. It can be recycled up to five times without losing quality. It does not shed plastic microfibers and resists static. Additionally, it holds colors well.

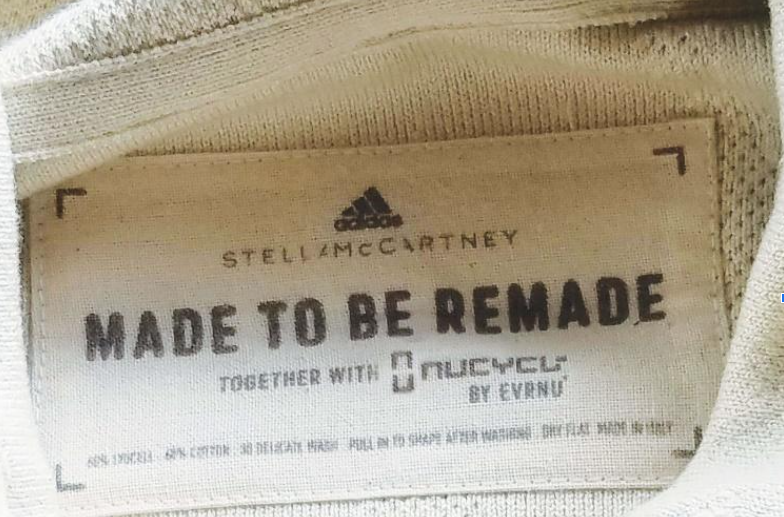

NuCycl technology has partnered with major brands to improve sustainable fashion. Stella McCartney used NuCycl fibers to create the first garment made from regenerated cotton—a custom hoodie. Adidas made a prototype hoodie with 60% NuCycl-regenerated cotton and 40% organic cotton, showcasing its versatility for performance wear. Levi’s produced jeans using NuCycl fibers, demonstrating how denim can be made sustainably. Target integrated NuCycl into home textiles like towels and bedding, making sustainable options available to everyday consumers. These collaborations highlight NuCycl’s potential to turn textile waste into high-quality fibers, promoting circular fashion and lowering the industry’s environmental impact.

References:

- https://www.evrnu.com/nucycl

- https://specialtyfabricsreview.com/2024/08/01/evrnu-creates-textile-waste-production-based-yarns-fibers/

- https://www.the-spin-off.com/news/stories/The-Materials-How-Evernus-NuCycl-can-make-a-difference-in-circular-textiles-16748

- See below Video

This innovative technology helps tackle the problem of textile waste by recycling old clothing into high-quality fibers, promoting a closed-loop system in the textile industry.