ETP is a type of wastewater treatment process that plays a crucial role in environmental protection and sustainability, basically designed to treat household and industrial wastewater and other types of sewage. A significant by-product of this wastewater treatment process is ETP sludge. Industrial wastewater treatment plants produce solids known as sludge. Sludge comes from biological or physical-chemical processes. It is a thick, semi-solid waste that collects at the bottom of the treatment plant. The sludge is then taken out of the system for treatment or disposal. This waste from the treatment plant is called ETP sludge.

ETP sludge generated from the textile industry is a complex mixture that contains diverse and often hazardous components produced during various textile processes like dyeing, printing, and finishing. The key components are:

Organic Matter:

ETP sludge contains a high percentage of organic dyes, acids, enzymes, and sizing materials originating from dyes, detergents, and other chemicals used in textile processing. Depending on the specific process involved, they can range from 10% to 70%.

Toxic Heavy Metals:

Metals are significant pollutants, both primary and secondary, and pose severe threats to aquatic life. Due to use of metal-based dyes and other chemicals textile sludge often contains heavy metals. The most toxic among them include chromium (Cr), cadmium (Cd), nickel (Ni), zinc (Zn), copper (Cu), lead (Pb), and iron (Fe), among others.

Physical Properties:

Textile sludge exhibits the following characteristics:

- Water content is 26.22%

- Specific gravity measures 2.66

- The pH level stands at 8.5

Sludge can be categorized into Primary and Secondary Sludge. Primary sludge is produced through sedimentation, chemical precipitation, or other primary processes. Secondary sludge arises from biological treatment and encompasses any sludge that accumulates if primary sludge undergoes further industrial processes.

In recent years efforts have been made for treating both household and industrial wastewater. However, the sludge produced from this is often dumped untreated into the environment. The untreated sludge causes toxins to become unstable, start to decompose, and spread diseases. So, we need to treat sludge before we dispose of it or reuse it.

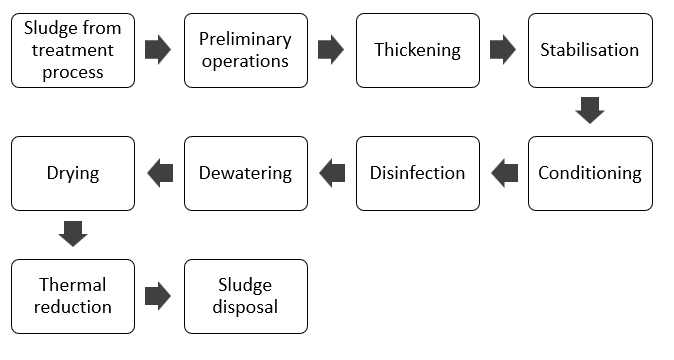

Different sludge treatment processes:

Reuse potential of Textile Sludge:

- Brick Manufacturing: Using textile sludge to make brick is a promising solution. Studies show that adding textile sludge creates a reusable product and helps of hazardous waste. We can mix the sludge with clay in amounts ranging from 5% to 35%. This method produces bricks that meet strength standards and reduce the need for topsoil, which is important for farming.

- Construction Materials: Apart from bricks textile sludge can be utilized in other construction materials including Cement concrete flooring tiles, pavement blocks, etc.

- Alternative fuel source: In the cement industry, treated sludge can serve as an alternative fuel due to its high calorific value (10-20 MJ/Kg) and lower carbon dioxide emissions compared to coal.

- Domestic Heating and Cooking: Sludge treated via anaerobic digestion can produce biogas (methane), which can be used for heating and cooking or converted into electricity.

- Agriculture and Landscaping: Treated sludge can be used in gardening, forestry, and parks. It can be also integrated into landscaping projects as it contains nutrients beneficial for plant and grass growth, aiding reforestation efforts. With its bulking and water retention properties, it is effective in controlling soil erosion, especially in sloped areas.

adding textile sludge creates a reusable product and helps of hazardous waste.