What is Antimicrobials for textiles?

Antimicrobials control, destroy or suppress the growth of microorganisms and their negative effects of odour, staining and deterioration on textile surface.

What is ANTI-MICROBIAL FINISHING on Textiles?

Anti-microbial finishing on fabric inhibits the growth of micro-organism such as bacteria, viruses, fungi, Algae, Mold, Mildew etc.. The application processes of antimicrobials are not same on fabrics. Some of antimicrobials work by leaching or moving from the surface on which they are applied. This is the mechanism used by leaching antimicrobials to poison a microorganism. The bound unconventional antimicrobial technology, an organo-functional silane, has a mode of action that relies on the technology remaining affixed to the substrate – killing microorganisms as they contact the surface to which it is applied. Effective levels of this technology do not leach or diminish over time. When applied, the technology actually polymerizes with the substrate making the surface antimicrobial.

This type of antimicrobial technology is used in textiles that are likely to have human contact or where durability is of value.

Pic.: Anti-microbial Finishing on Textiles.

What are the necessities of Antimicrobial Finishing on Textiles?

Antimicrobial treatment for fabric is done for below reason…

- To control microorganisms

- To reduce odour from perspiration, stains and other soil on textile material

- To reduce the risk of cross infection being carried by feet from ward to ward in hospital

- To control spread of disease and danger of infection following injury

- To control the deterioration of textiles particularly fabrics made from natural fibre caused by mildew

What are the requirements for Antimicrobial Finish on Textiles?

Textile materials in particular, the garments are more susceptible to wear and tear. It is important to take into account the impact of stress strain, thermal and mechanical effects on the finished substrates. The following requirements need to be satisfied to obtain maximum benefits out of the finish:

- Durability to washing, dry cleaning and hot pressing

- Selective activity to undesirable microorganisms

- Should not produce harmful effects to the manufacturer, user and the environment

- Should comply with the statutory requirements of regulating agencies

- Compatibility with the chemical processes

- Easy method of application

- No deterioration of fabric quality

- Resistant to body fluids

- Resistant to disinfections/sterilization.

What are the methodologies for Antimicrobial Finishing?

The antimicrobial agents are generally applied to the textile materials by exhaust, pad-dry-cure, coating, spray and foam techniques. The chemicals can also be applied by directly adding into the fibre spinning dope. It is claimed that the antimicrobial chemicals can be applied online during the dyeing and finishing operations. Various methods for improving the durability of the finish include:

- In solubilization of the active substances in/on the fibres.

- Treating the fibre with resin, condensates or cross linking agents.

- Micro encapsulation of the antimicrobial agents with the fibre matrix.

- Coating the fibre surface.

- Chemical modification of the fibre by covalent bond formation.

- Use of graft polymers, homo polymers and/or co polymerization on to the fibre.

What is the Mechanism of Anti-Microbial activity?

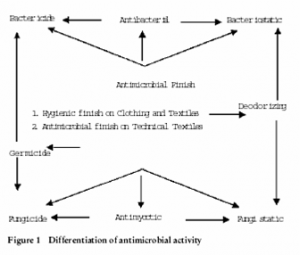

Negative effect on the vitality of the microorganisms is generally referred to as antimicrobial. The degree of activity is differentiated by the term ëcidalí that indicates significant destruction of microbes and the term ecstatic represents inhibition of microbial growth without much destruction. The differentiation of antimicrobial activity is given in the diagram (Figure 1).

The activity, which affects the bacteria, is known as antibacterial and that of fungi is antimycotic. The antimicrobial substances function in different ways. In the conventional leaching type of finish, the species diffuse and poison the microbes to kill. This type of finish shows poor durability and may cause health problems. The non-leaching type or bio-static finish shows good durability and may not provoke any health problems. A large number of textiles with antimicrobial finish function by diffusion type. The rate of diffusion has a direct effect on the effectiveness of the finish. For example, in the ion exchange process, the release of the active substances is at a slower rate compared to direct diffusion ad hence, has a weaker effect. Similarly, in the case of antimicrobial modifications where the active substances are not released from the fibre surface and so less effective. They are active only when they come in contact with microorganisms.

Considering the medical, toxicological and ecological principles has developed these so called new technologies. The antimicrobial textiles can be classified into two categories, namely, passive and active based on their activity against microorganisms. Passive materials do not contain any active substances but their surface structure (Lotus effect) produces negative effect on the living conditions of microorganisms (Anti-adhesive effect). Materials containing active antimicrobial substances act upon either in or on the cell.

What are the uses of Nano-technology for Anti-microbial Finishing on Textiles?

The prefix nano in the word nanotechnology means one billionth of a meter (1×10-9). Nanotechnology deals with various structures of matter having the dimension of the order of a billionth of a meter. Structures on this scale have been shown to have unique and novel functional properties. Based on that principle, many applications of nanotechnology from the simple to the complex have been done.

One of these applications is to prepare antimicrobial textiles based on heavy metals in their nanoscale. Particles at the nanoscale are below the wave length of visible light and therefore, cannot be seen. Consequently they can impart new properties. For example, Ti-nanoparticles are applied for the textile materials in order to develop textile products with UV- protection and self cleaning property. Also Silver nanoparticles are used as antimicrobial agent for wound dressing materials as well as for wound healing. In addition, the production of fibers with diameter less than 100nm is now feasible with the invention of electro-spinning process. Electro-spinning is a manufacturing new technology capable of producing thin, solid polymer strands from solution by applying a strong electric field to a spinneret with a small capillary orifice. The spun, polymer based nano-fibers, can be loaded with different additives which could be metal nanoparticles like silver, drugs or catalysts depending on the required applications. The resulted nano-fibers are collected and bundled. These electro-spun fibers have high surface area and porous structure, where more than one drug can be encapsulated directly into the fiber. The resulted matrix can be used extensively for medical textiles production with multifunctional properties.

The use of nanoparticles of silver, gold and zinc oxide has been seen as a viable solution to stop infectious diseases due to the antimicrobial properties of these nanoparticles. In view of the textile industry’s innovative history, it is no wonder that nanotechnology has found its way into this sector so quickly. Nanotechnology is forecasted as the second industrial evolution in the world.

With growth in world population and the spread of disease, the number of antibiotic resistant microorganisms is rising along with the occurrence of infections from these microorganisms. With this increase in health awareness, many people focused their attention on educating and protecting themselves against harmful pathogens. It soon became more important for antimicrobial finished textiles to protect the wearer from bacteria than it was to simply protect the garment from fiber degradation. The need for antimicrobial textiles goes hand-in- hand with the rise in resistant strains of microorganisms. Functional textiles include everything from antimicrobial finished textiles, to durable, or permanent press finished garments, to textiles with self-cleaning properties, and also textiles with nanotechnology.

Pic.: Nano-Technology for anti-microbial finishing on textiles.

What is sol-gel technology for antibacterial finishing of textiles?

The sol-gel process is known as chemical solution deposition, it is a wet-chemical technique that is widely used. In this chemical procedure, the ‘sol’ (or solution) gradually evolves towards the formation of a gel-like diphasic system containing both a liquid phase and solid phase whose morphologies range from discrete particles to continuous polymer networks. In the case of the colloid, the volume fraction of particles (or particle density) may be so low that a significant amount of fluid may need to be removed initially for the gel-like properties to be recognized. This can be accomplished in any number of ways. The simplest method is to allow time for sedimentation to occur, and then pour off the remaining liquid. Centrifugation can also be used to accelerate the process of phase separation. Removal of the remaining liquid (solvent) phase requires a drying process, which is typically accompanied by a significant amount of shrinkage and densification. The rate at which the solvent can be removed is ultimately determined by the distribution of porosity in the gel. The ultimate microstructure of the final component will clearly be strongly influenced by changes imposed upon the structural template during this phase of processing.

The precursor sol can be either deposited on a substrate to form a film (e.g., by dip coating or spin coating), cast into a suitable container with the desired shape (e.g., to obtain monolithic ceramics, glasses, fibers, membranes, aerogels), or used to synthesize powders (e.g., microspheres, nanospheres) . The sol-gel approach is a cheap and low-temperature technique that allows for the fine control of the product’s chemical composition. Sol-gel derived materials have diverse applications in optics, electronics, energy, space, (bio) sensors, medicine (e.g., controlled drug release), reactive material and separation (e.g., chromatography) technology and in the production of antimicrobial textiles.

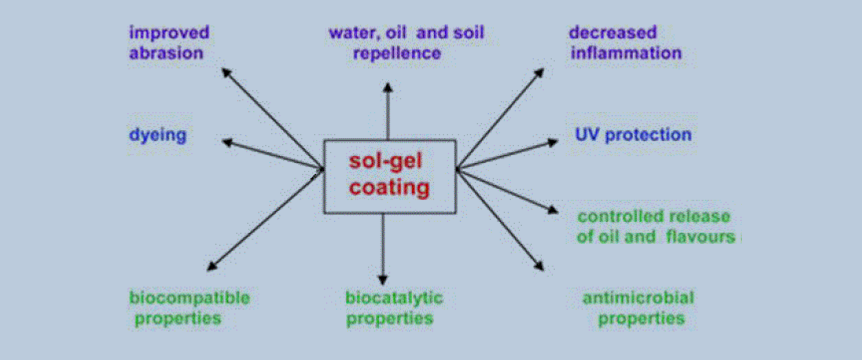

Recently, investigations have been conducted to improve properties of textile fabrics by embedding various finishes in sol-gel coating to enhance fabric performance. The following section will focus on different sol-gel applications that create new functional properties in textile fabrics. Textiles coated with sol-gel are reported to impart many important properties.

Pic.: Different applications of sol-gel coating on textiles

What are the processes of Evaluation of antimicrobial efficacy?

A number of test methods have been developed to determine the efficacy of antimicrobial textiles. These methods generally fall into two categories: the agar diffusion test and suspension test.

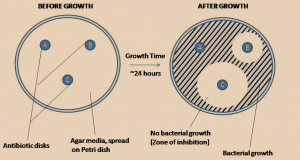

Agar diffusion test:

Agar diffusion test is a preliminary test to detect the diffusive antimicrobial finish. It is not suitable for non diffusive finishes and textile materials other than fabrics . The agar diffusion tests include AATCC 147-2004 (American Association of Textile Chemists and Colorists), JIS L 1902-2002 (Japanese Industrial Standards) and SN 195920- 1992 (Swiss Norm). They are only qualitative, but are simple to perform and are most suitable when a large number of samples are to be screened for the presence of antimicrobial activity. In these tests, bacterial cells are inoculated on nutrient agar plates over which textile samples are laid for intimate contact. The plates are then incubated at 37°C for 18–24 h and examined for growth of bacteria directly underneath the fabrics and immediately around the edges of the fabrics (zone of inhibition). No bacterial growth directly underneath the fabric sample indicates the presence of antimicrobial activity. The zone of inhibition should not be expected if the antimicrobial agent is firmly attached to the textile (e.g. covalently) which prevents its diffusion into the agar. If the antimicrobial agent can diffuse into the agar, a zone of inhibition becomes apparent and its size provides some indication of the potency of the antimicrobial activity or the release rate of the active agent .

Pic.: Agar diffusion test

Suspension test:

This type of test is exemplified by AATCC 100-2004, JIS L 1902-2002 and SN 195924-1992. These methods provide quantitative values on the antimicrobial finishing, but are more time-consuming than agar diffusion tests. Typically, a small volume (e.g. 1 ml) of bacterial inoculums in a growth media is fully absorbed into fabric samples of appropriate size without leaving any free liquid. This ensures intimate contact between the fabric and the bacteria. After incubating the inoculated fabrics in sealed jars at 37°C or 27°C for up to 24 h, the bacteria in the fabric are eluted and the total number is determined by serial dilution and plating on nutrient agar plates. Antimicrobial activity, expressed as percentage of reduction, is calculated by comparing the size of the initial population with that following the incubation. Appropriate controls, e.g. samples that have gone through the same processing except the antimicrobial finishing, should be included in each experiment to ascertain that the observed decrease in bacterial number is truly due to the antimicrobial finishing.

It should be noted that suspension tests are often performed under artificial conditions that promote bacterial growth (e.g. rich nutrients in the inoculum and saturating moisture in the testing fabrics). The moisture in the tests is also essential for the action of the biocide. As a result, dramatic results are often produced (e.g. >99% bacterial cells are killed during the assays), leading to an overwhelming impression of the efficacy of the antimicrobial ability.

However, such conditions are rarely found during the normal use of a textile product. To date, very few studies have examined the antimicrobial effects under normal wearing conditions. To more closely mimic the real-life situation, the JIS L 1902-2002 method recommends the use of bacterial cells suspended in heavily diluted nutrient media to limit nutrient levels.

The ISO (International Organization for Standardization) has developed a test method (ISO 20743) in which bacteria are “printed” onto the surface of textiles without them being in an aqueous suspension. The printed samples are then incubated under humid conditions at 20°C for a specified time (18–24 h) following which the surviving cells are counted. Antimicrobial tests only assess the antimicrobial effectiveness of the treated textiles. Before marketing, the textile products have to pass biocompatibility tests which involve three separate assays: cytotoxicity, sensitization and irritation. These assays are outside the scope of this chapter but are discussed elsewhere.

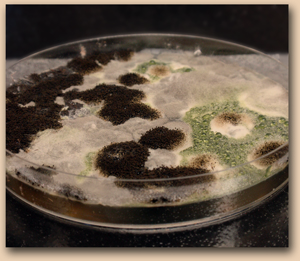

Pic.: Suspension test; Fungi on agar surface

What are the benefits of Antimicrobial Textiles?

A wide range textile product is now available for the benefit of the consumer. Initially, the primary objective of the finish was to protect textiles from being affected by microbes particularly fungi. Uniforms, tents, defense textiles and technical textiles, such as, geotextiles have therefore all been finished using antimicrobial agents. Later, the home textiles, such as, curtains coverings, and bath mats came with antimicrobial finish. The application of the finish is now extended to textiles used for outdoor, healthcare sector, sports and leisure. Novel technologies in antimicrobial finishing are successfully employed in non-woven sector especially in medical textiles. Textile fibres with built-in antimicrobial properties will also serve the purpose alone or in blends with other fibres. Bioactive fibre is a modified form of the finish, which includes chemotherapeutics in their structure, i.e., synthetic drugs of bactericidal and fungicidal qualities. These fibres are the only used in medicine and health prophylaxis applications but also for manufacturing textile products of daily use and technical textiles. The field of application of the bioactive fibres includes sanitary materials, dressing materials, surgical threads, materials for filtration of gases and liquids, air conditioning and ventilation, constructional materials, special materials for food industry, pharmaceutical industry, footwear industry, clothing industry, automotive industry etc.

What are the considerations needed during anti-microbial finishes?

To benefit from the consumer demand for antimicrobial/antibacterial products and for the antibacterial and antifungal performance needs of the textile world, manufacturers have a choice. In choosing, they should utilize a treatment that provides for an odor reduction/antibacterial claim and an antimicrobial finish for their textile products consistent with their claims and the needs of their target consumers. This selection should be done by considering:

- Adopting an antimicrobial technology with a proven history of use. This will help shorten the timelines in bringing products with an antibacterial/antifungal/odor-reducing, antimicrobial feature to market.

- Adopting a non-leaching antimicrobial that doesn’t pose the risk of crossing the skin barrier. If it creates a “zone of inhibition” it leaches or moves and has the potential to cause problems.

- Adopting a non-leaching antimicrobial that doesn’t pose the risk of creating adaptive resistant microorganisms.

- Adopting an antimicrobial technology that can have its proper application tested for at the mill or at the retailers. A verifiable quality assurance program should be a key component of any application process.

Adopting an antimicrobial technology that has technical and marketing support, Numerous retail buyers have stated that the antimicrobial/antibacterial “feature” is quickly moving to a standard requirement for the products that they buy. Manufacturers that don’t currently treat fabrics with a durable antimicrobial finish should consider shielding their products from eroding value by incorporating microbial control. As manufacturers look to enhance the value of their products they should recognize antimicrobial finishes as a feature with a future and the future is now.

REFERENCES:

- Antimicrobial Finishes By Gopalakrishnan & R K Aswini

- Antibacteria Modification of Textiles Using Nanotechnology By Moustafa M. G. Fouda.

- www.fibre2fashion.com