In textile engineering, fabric finishing is the transformative final stage that elevates raw textiles into high-quality, market-ready products. This crucial process not only enhances the fabric’s appearance and feel but also improves its durability and functionality—aligning the final product with specific consumer expectations.

What is Fabric Finishing?

Fabric finishing refers to a series of mechanical, chemical, or thermal treatments applied to woven or knitted fabrics after production. These processes enhance the look, texture, performance, and usability of the fabric—making it suitable for its intended purpose.

Common Fabric Finishing Techniques:

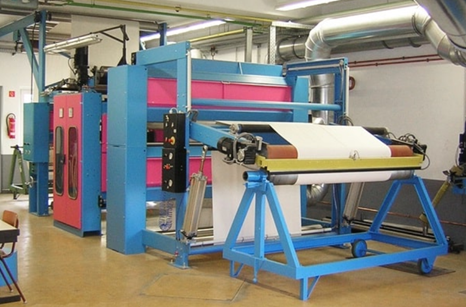

Calendaring:

A mechanical process where the fabric is passed through heated rollers to produce a smooth, glossy finish—commonly used for linings and dress materials.

Pic:Calendering machine; Source: textilelearner.com

Singeing:

Protruding surface fibers are removed by exposure to flames or heated plates, resulting in a cleaner and smoother fabric.

Pic: Singeing; Source: textile blog

Mercerization:

A chemical treatment using caustic soda (NaOH), mostly for cotton fabrics, to increase luster, strength, and dye affinity.

Pic: Mercerization; Source: threadmagagine.com

Sanforization:

A pre-shrinking process that ensures dimensional stability, preventing shrinkage during washing or wear.

Pic: Sanforization machine; Source: advancetextile86

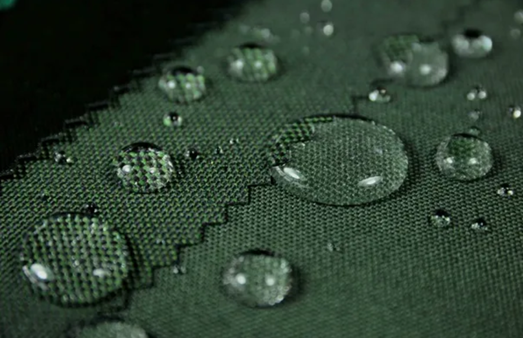

Water Repellent Finish:

Chemical coatings such as fluorocarbons or silicones are used to make the fabric resistant to water without sacrificing breathability.

Pic: Water Repellent Finish; Source: textilelearner.com

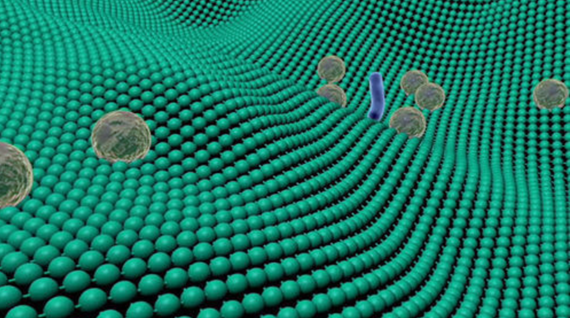

Anti-microbial & Anti-odor Finishes:

Crucial for activewear and medical textiles, these finishes inhibit bacterial growth and odor, promoting hygiene and freshness.

Pic: Anti-microbial & Anti-odor Finishes; Source: textile research & development

Why Fabric Finishing Matters:

Fabric finishing matters because it significantly enhances the overall quality, functionality, and appeal of textile products. By applying specific treatments—mechanical, chemical, or thermal—it improves the fabric’s texture, appearance, durability, and comfort. Finishing processes add valuable properties such as wrinkle resistance, water repellency, antimicrobial protection, and shrink control, making fabrics more suitable for end-use applications. Ultimately, fabric finishing transforms raw textiles into high-performance, consumer-ready materials that meet aesthetic and functional expectations.

Sustainability in Fabric Finishing:

With growing environmental concerns, the textile industry is embracing eco-conscious innovations. Technologies like enzyme-based finishes, low-water chemical processing, and plasma treatments are making fabric finishing more sustainable, safe, and efficient.

Conclusion:

Fabric finishing isn’t merely the final step in production—it’s the defining touch that transforms basic fabric into a high-quality, functional, and desirable product. As textile trends continue to evolve, the role of innovative and sustainable finishing techniques becomes more essential than ever.

Reference:

1. Kadolph, S. J. (2010). Textiles (11th ed.). Pearson Education.

2. Gohl, E. P. G., & Vilensky, L. D. (2005). Textile Science: An Explanation of Fibre Properties. Longman.

3. Wingate, I. B. (1976). Textile Fabrics and Their Selection (7th ed.). Prentice Hall.

4. Textile Learner. (n.d.). Fabric Finishing Process in Textile. Retrieved from https://www.textilelearner.net

5. Fibre2Fashion. (n.d.). Fabric Finishing – Adding Value to Fabric. Retrieved from https://www.fibre2fashion.com

6. ScienceDirect. (n.d.). Articles on Sustainable Textile Finishing. Retrieved from https://www.sciencedirect.com