Oceans are the lungs of the Earth. They contain phytoplankton, cyanobacteria, seaweeds, algae etc. that contribute to most of the atmospheric oxygen but we, so-called civilized human beings leave traces of pollution wherever we go.

Each year, about 14 million tons of plastic enter the ocean. Plastic bottles, polyethene bags, large debris release microplastics which affects over 500 species through entanglement and ingestion and causing death. Plastic pollution threatens human health via food chain. Higher CO2 levels increase ocean acidification which destroys corals and creates toxic algal blooms.

Bionic yarn is an upcycled product that aims to eliminate plastic pollution. Made from fusion of recycled plastic and high-quality natural fiber, this yarn shows a promising future for sustainability. The resulting yarn is of superior quality and is used by high-end retailers like Timberland and G-Star Raw and in fashion projects like ESA Couture in Orbit.

Different Types of Bionic Yarn and their Properties:

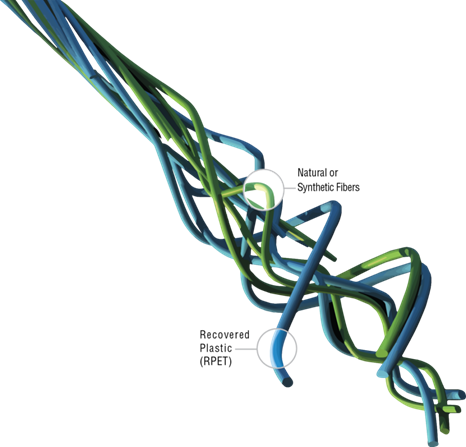

DPX®

It is a dual staple fiber construction which blends recycled PET with other synthetic or natural fibers closely. DPX forms a customizable yarn having soft texture. It has applications in apparel, bags, luggage, footwear and interiors. Plain, twill and jacquard fabric are produced from it. These include- DPX JQYD 11.2, DPX Pin Point, DPX 3RSYD H5.2, DPX Shirting 137 etc.

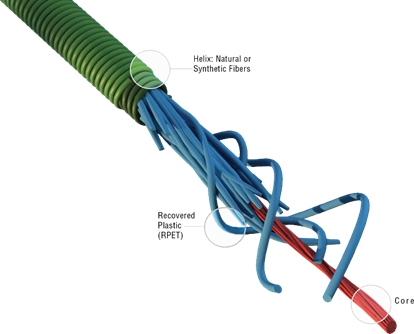

HLX®

This patented performance yarn provides durability and sophisticated quality. HLX® yarn structure creates a refined surface texture through its helical shell and immerses RPET under the surface. The helix can also enhance the abrasion resistance on natural fabrics while retaining its aesthetics. HLX® yarn has applications in apparel, bags & luggage, footwear and interiors. Plain and Twill fabric are made from it such as- HLX280SH PL H6.9 3L, HLX280SH TWL H5.4 2L, HLX280SH TWL P8.3 etc.

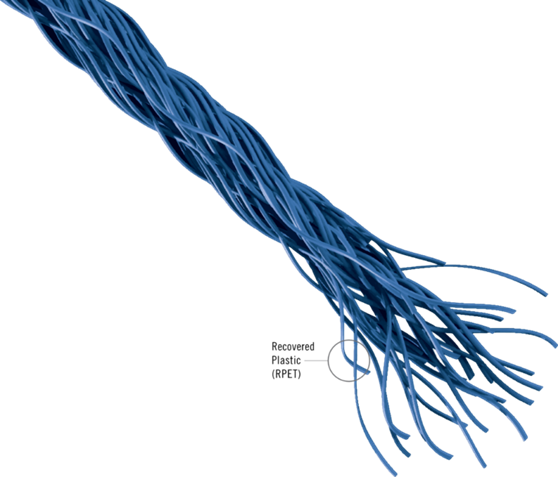

FLX™

FLX™ is a continuous filament yarn. Dozens of Recovered Plastic (RPET) filaments are heated and spun into a durable yarn with a variety of performance and aesthetic properties. It has applications in apparel, bags and luggage, footwear and interiors. Basketweave and Jacquard fabric are made from it such as- FLX 800d Basketweave, FLX X-Pattern, FLX JQYD 11.4 etc. Special finish like Polyurethane can also be applied here.

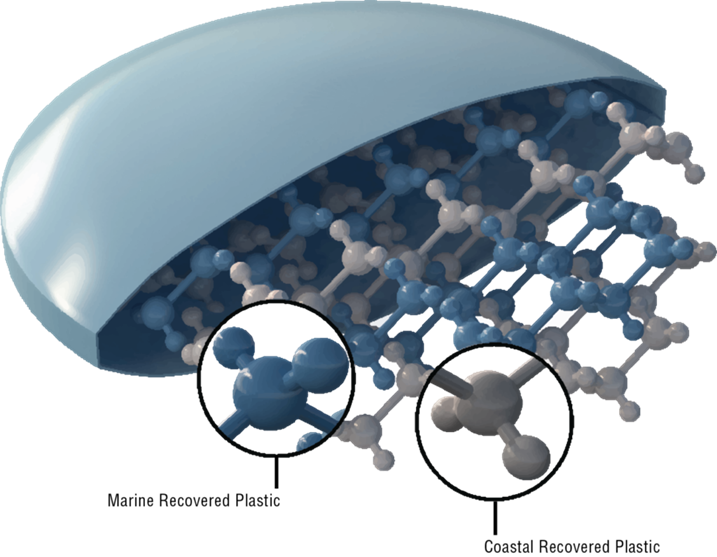

Bionic Polymer:

BIONIC® polymer is suitable for a wide range of hard plastic applications having no loss in performance. They tailor specific gravity, melting point, melt index, tensile strength, elongation, elastic modulus, and color to each unique product. It comprises of marine recovered plastic and coastal recovered plastic and can be roto-molded, blow-molded, or injection-molded.

References:

- https://bionicyarn.com

- https://www.esa.int/Science_Exploration/Human_and_Robotic_Exploration/Couture_in_orbit/A_stronger_thread