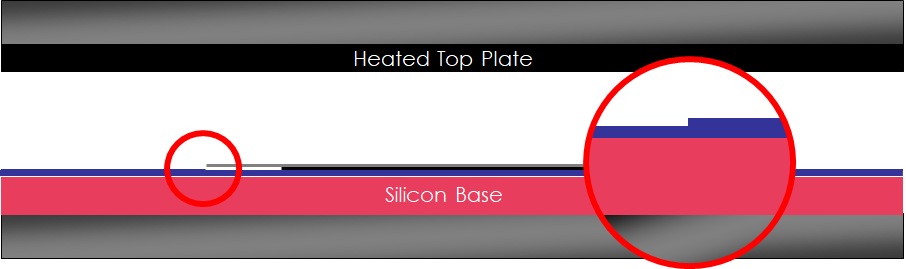

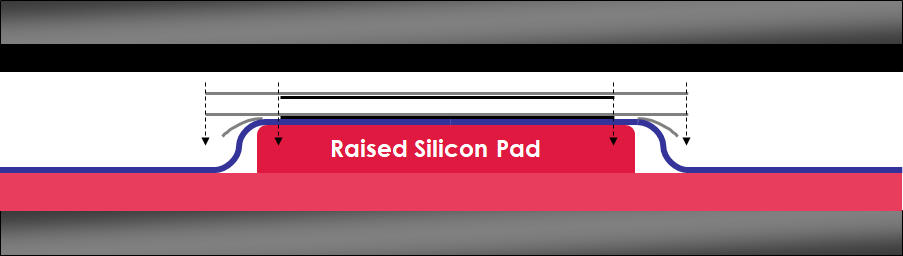

For heat Transfer printing impression mark is common scenario that is visible on garments after heat press on garments. Below is the one way to avoid impression mark on the garment surface. If the transfer film/paper is leaving an impression mark on the fabric, you need to cut a block of Silicon Rubber, approximately 1cm larger than the transfer image size. This block should then be rounded off around all of the edges by approximately 1-2mm. This is then placed on the bed of the machine and fabric is placed on top of this. The transfer film should then overlap the edge of this block and not mark the fabric. Please note, Adding this block will change the applied pressure, so consult with the transfer supplier to calculate the correct pressure settings for this new base size.

Why does a Transfer print leave an impression mark on fabrics ?

Generally below are the main issues why the impression mark is visible for heat transfer print.

- Position the fabric on top of the Base Plate

- Position the Heat Transfer on top of the fabric

- Start Machine Transferring

- Allow to cool down before peeling off the Transfer Film

- The pressure means that the edges of the Transfer Film leaves an indentation on the fabric

How to stop an impression mark on fabrics during Heat Transfer Print ?

To avoid impression mark, you can follow the below steps and will have better results.

- Create a correctly sized raised Silicon Pad

- The size should be between the image and the edges of the transfer film and have rounded edges

- Position the fabric on top of the raised Silicon Pad

- Place the Heat Transfer in the correct position

- Start machine transferring

- Notice that the transfer film does not touch the edges of the fabric

- Allow To cool before peeling off the Transfer Film

- This way, the transfer film will not leave an impression mark on the fabric

Also make sure that you place the Raised Silicon Pad in the centre of the machine base.

![]()

Adding a Raised Silicon Pad changes the parameters of the base-plate area of the machine, therefore the required applied pressure will be different. This will need to be recalculated to allow the correct pressure to be applied to the new surface area of the Heat Transfer.

Source :

- Training from NSLBD Garment technical team

- Photo by Francesco Paggiaro: https://www.pexels.com