Modern tools:

Higher productivity brings higher margin in a business. And increment in Productivity level reduces garment manufacturing cost. Hence factory can make more profit through productivity improvement.

To increase production, various models of those machineries are used that are equipped with various features like automatic thread trimmer, folder, guide knee lifter, color display etc.

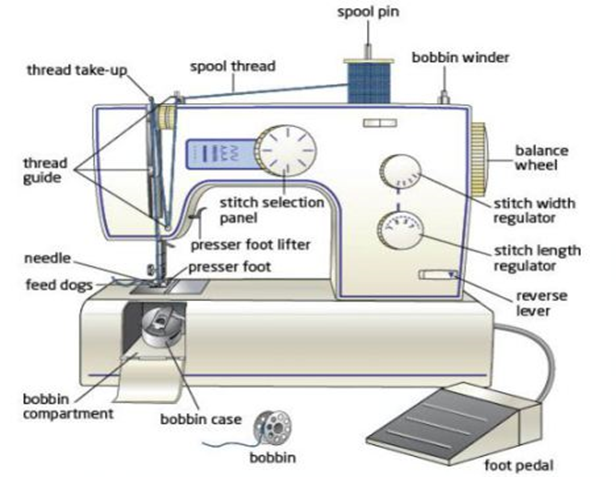

HAND WHEEL:

Hand wheel on a modern sewing machine is smaller in size as compared to the one found in traditional models. It performs the function of lifting or lowering the needle.

FOOT PEDAL:

Foot pedal for controlling the speed and power switch for operating the machine are other components.

STITCHING PATTERN DIAL:

Stitching pattern dial is an innovative and an extremely useful component of the modern models. As the name suggests, it helps the user to select among different stitching patterns and styles.

PNEUMATIC TYPE NEEDLE THREAD/LOOPER THREAD TRIMMING DEVICE:

It is a pneumatic type needle thread/ looper thread trimming device/auto lifter. Since the automatic lift of the presser foot and automatic thread trimming can be activated by lightly depressing the pedal, work efficiency is dramatically increased.

TIMING BELT:

In some modern machines instead of gear timing belt is used which enable machine run faster and quiet even if high speed, result will be a wonderful stitch quality.

AUTOMATIC ONE PEDAL UNIT:

This new unit incorporating an automatic device requires only one pedal operation to start or terminate buttonholing. The work clamp check comes down or goes up automatically through this automatic device developed. Accordingly this unit may allow one operator to attend to two machines.

SAFETY DEVICE:

Safety device is used to prevent knife from being dropped in case of needle thread breakage. If the needle thread should break while sewing, this safety will prevent the knife from being dropped, and therefore chance for damage to work pieces under process is eliminated.

NON ROTARY BOBBIN:

The non-rotary bobbin eliminates irregular stiches which have a tendency to occur at some sewing speeds and bobbin thread tension fluctuations which have a tendency to occur according to the bobbin thread remaining on the hook. Since the bobbin thread is fed without rotating the bobbin, the bobbin never idles.

NEEDLE THREAD FEEDING DEVICE:

This part feeds the needle thread by only the required length at the beginning of sewing. it prevents stitch skipping and slip –off of the needle thread. It also greatly improves workability by shortening the thread remaining at the needle after it is trimmed.

MICRO LIFTER SCREW:

Some machine is provided as standard with a micro lifter screw. This helps to prevent material slippage or damages when using elastic materials.

ADVANCED OPERATION PANEL:

A liquid crystal display has been adopted in most modern machines.it displays stitch shape, stitch width. No of stitch per inch, rpm, standard lines with pictographs and settings all together on one screen to improve operability of the panel.

TENSION CONTROLLER:

Most sewing machines have a tension-control dial that’s used to control the tension of the upper thread. This is important to help stitches form correctly.

Some dials have the tension for the most commonly used stitches highlighted on them.

POWER SWITCH:

It has to be said: sewing machines run on electricity (well, most do). There should be a cord attached to the foot pedal that plugs into the wall and the machine. The power switch is usually on the right side of the machine.

KNEE LIFTER

A knee-lifter is useful for free hand embroidering with a machine Found on only a few sewing machines, a knee lifter is a lever which can be pressed with knee, allowing to lift the presser foot and drop the feed dogs without taking hands off our work.

It enables to move the fabric freely for quilting, sewing around curves and embroidery – ideal for large projects, or giving an extra hand for fiddly jobs.

TENSION DISCS AND TENSION REGULATOR:

The tension discs squeeze the thread as it passes between them and the tension regulator controls the amount of pressure on the discs. Luckily for the modern sewer if turn the dial to a higher number, the tension is increased, and if turn the tension to a lower number, the tension is decreased. When the tension is correct, the stitched line is straight, smooth and even on both sides of the fabric. There are no loops or knots in the line, and the knot between the top and bottom threads is hidden between fabric layers.

STITCH SELECTOR:

The stitch selector controls where the needle moves as it to stitches, which governs what the stitch looks like. For instance, if the needle alternates left and right between stitches it creates a zigzag stitch. More expensive machines select a stitch by pressing a button or using a touchpad. Stitch length control dial is also a useful component that allows the user to choose among fine and long stitches for different types of fabrics.

References: