Water is an essential component of textile dyeing. It acts as a solvent, holding all the other components together and stimulating them to interact with each other. However, our resources are scarce, and a tremendous amount of water is spent in textile wet processing. It takes 20,000 litres of water to make a single t-shirt, equivalent to the drinking requirement of a person for 3 years. And waterless dyeing using Supercritical Carbon dioxide comes into play here.

What is Supercritical CO2?

When a gas exceeds its critical point, it converts into a Supercritical fluid. At this stage, it can act as a solvent that is non-toxic, non-flammable and chemically inert. The critical point of CO2 is Tc = 31.1 °C and Pc = 73.7 bar, which is easily accessible.

At this stage, CO2 has a high diffusion power that enables it to dissolve the dye particles easily. Due to its high permeability, dye molecules are bonded perfectly with the substrate or fibres. As a result, colourful textiles are produced. In this method, the dye uptake is nearly 98%, with negligible amount of unfixed dyes.

The Mechanism behind it

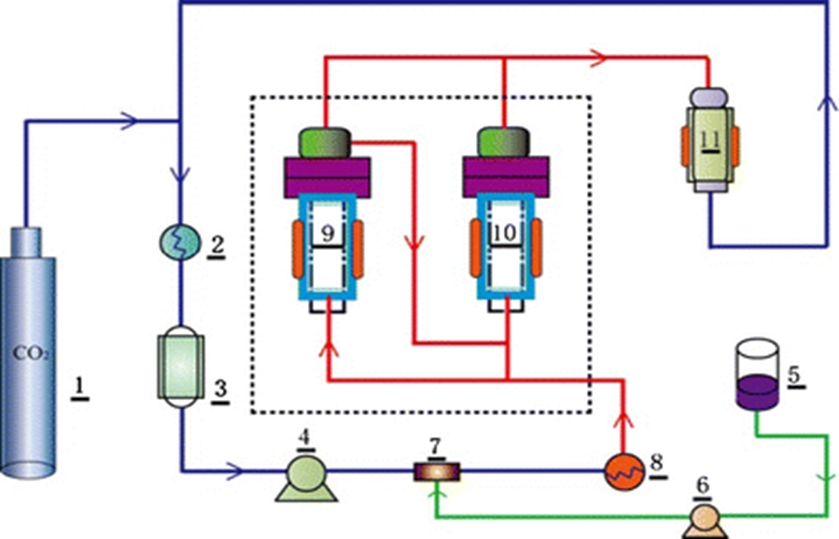

Pre-treatment: The fabric is cleaned and made free from pollutants, wax, oil and other hydrophobic substances as they can hamper the dyeing process. Liquid CO2 from Buffer tank is compressed to supercritical pressure by Pressurization pump. It is taken to supercritical temperature by Heat Exchanger. The supercritical fluid is then passed through the fabric in dyeing autoclave. When it flows through an expansion valve, pressure decreases. The extracted foreign particles are collected in the Separator. CO2 is then liquefied in the Condenser and is taken back to the Buffer tank.

Dyeing: Dyestuff receiver is introduced into the CO2 circulation. Dye particles are dissolved into supercritical CO2 in dyeing autoclave. The dye molecules are adsorbed in the fibers.

CO2 then flows through a filter to the circulating pump. Afterwards, it is again passed in the dyestuff receiver with fresh dyestuff, until the desired dyeing intensity is reached.

After Treatment: When dyeing process is finished, residual dyestuff is removed from supercritical CO2 and dyed material. CO2 is taken out and expanded via the expansion valve into the separator. The residual dyestuff is collected in the separator. CO2 circulation ceases and the dyeing autoclave is brought to atmospheric conditions. The dyed fabric is taken out.

DyeCoo and SUPRAUNO®– Industry Pioneers in CO2 dyeing

DyeCoo- based in Hoofddorp, the Netherlands uses patented technology based on CO₂. In a closed-loop process, SC-CO₂ or Supercritical CO2 and 100% pure dyes ensure top notch dyed textile that uses zero water.

SUPRAUNO® developed by Deven Supercriticals is a patented sustainable waterless dyeing and finishing technology which uses Supercritical CO2 as the medium instead of water. Optimum quantity of dyes and auxiliaries are used for pre-coating to enhance rate of solubilisation in Supercritical CO2.

Advantages

Zero Water: The process uses zero water which ensures preserving our natural resources.

Zero Wastewater: Wastewater is not generated as there is no dye solution. As a result, harmful chemicals do not get mixed with waterbodies. The environment is conserved.

Better dyeing outcome: The dye uptake is maximum, contributing to perfect first time. Quality of the CO2-dyed textile is better than those dyed traditionally.

No drying process: There is no dyeing process and therefore no drying devices are necessary.

Low dye and chemicals consumption: In this waterless process, less amount of dyes and chemicals are required. Hence it is cost-efficient.

No damage of the fibers: The process does not create much friction on the fabric surface, leading to no damage of the fibers.

Energy savings: Less machineries are required and less energy, power and operational costs occur. Hence, it is energy efficient.

Final Takeaway

Supercritical carbon dioxide dyeing is a prospective dyeing process that is cost-efficient, energy efficient and eco-friendly. Moreover, better quality of dyed materials is achieved. Supercritical CO2 is cheap and easily recyclable, ensuring sustainability and circularity.

References

Really interesting read, I had no idea supercritical carbon dioxide could make dyeing more sustainable, this feels like a big step forward for the textile industry.