The history of the coloring of fabric is almost thousands of years old. Before W. H. Perkins discovered synthetic dyes in 1856, all the coloring pigments were made from natural pigments and oil. Nowadays, almost 90% of our clothes are used synthetic colors. Unfortunately, Textile is one of the largest and most polluting industries in the world. However Different natural and eco-friendly dyeing methods have been developed to lessen the harmful effects of textile production while also meeting the growing demand for ethical and sustainable fashion. In this scenario, there has been an increase in interest in sustainable dyeing, one of which is the use of hybrid pigments.

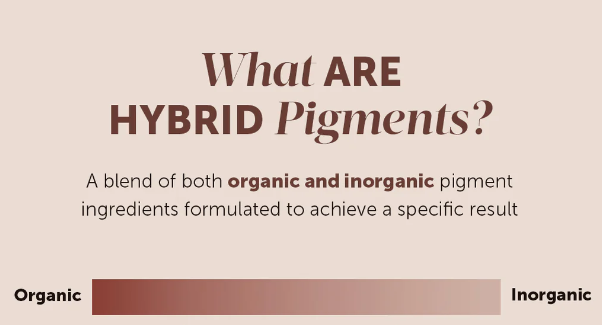

Understanding Hybrid Pigment:

Since ancient times, pigments have been widely used. They can be synthetically made from suitable raw materials or from naturally occurring substances prepared from minerals or their combustion products. Hybrid pigments are a new class of colorants that are made from both organic and inorganic components to create a versatile and sustainable coloring solution for fabrics.

As the name implies, hybrid pigments are formed by the conjugation of organic dye molecules with inorganic particles. This marriage combines the excellent light fastness and wash fastness of pigments with the vibrant color and simplicity of the application of dyes. The resultant hybrid improves textile coloring’s overall performance by providing the best of both worlds.

Types of Hybrid Pigments:

There are various types of hybrid pigments, each with its own advantages and applications:

- Dye-polymer hydrides: These consists of chemically attaching dye molecules to polymer particles, enabling a better washing-off process and low-temperature dyeing.

- Nanocomposite Hybrids: These add antimicrobial and light fastness qualities as well as thermal stability to the pigment structure by incorporating nanoparticles such as metal oxides or clays.

- Organic-inorganic hybrids: Through covalent bonds, these combine organic and inorganic compounds, directly producing remarkable color depth and durability.

Application Hybrid Pigments:

- Enhancing color fastness:

1- Hybrid pigments applied in textiles have better color fastness, meaning that colors stay vibrant even after numerous washings and light exposure.

2- They become more resistant to fading when organic and inorganic components are combined as the stability of colors is improved.

- Reduced environmental impact:

Hybrid pigments require less water and energy for dyeing processes, minimizing their harmful footprint on the environment. Moreover, their low waste generation and easy recycleability also contribute to environmental sustainability.

- Improved Functionality:

Additional features like UV protection, odor control, and antimicrobial capabilities, adding value and utility to the fabric can be found when hybrid pigments are infuse in textile. - Versatility:

Both Synthetic like polyester and nylon, as well as Natural fibers like cotton and wool can be printed with hybrid pigment.

Disadvantages :

- Higher Cost: These are often more expensive than traditional pigments due to their complex development.

- Technical Challenges: The application of hybrid pigments sometimes requires specific tools and procedures, adding to the initial investment for textile manufacturers.

- Limited Color Palette: While the available color options are expanding, the hues achievable in the case of hybrid pigments are currently somewhat smaller than traditional dyes.

Conclusion:

Hybrid Pigments represents a cutting-edge approach to coloration, offering a blend of increased performance, adaptability, and environmental sustainability. As ongoing research continues to refine these pigments, the textile industry can expect more inventive solutions for vibrant and durable coloration.

References:

2-https://www.angadcreations.com