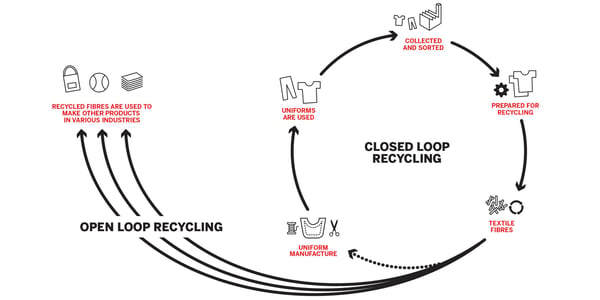

What is a Closed-Loop textile system?

A closed-loop system is a design and manufacturing method that keeps the textile material circulating for as long as possible. Here the main concentration is set on recycling. Unlike open-loop, the fibers produced through the closed-loop process, are used in textile later.

Main purpose Closed-Loop textile system:

The main focus of this system is efficient usage of wastage. To do it properly, plants concentrate on the following.

- Minimum Waste Generation

- Minimum hazardous effects on the environment

- Most use of water resources

- Minimum generation of wastage.

How is the loop closed?

The process is quite simple to understand. The initial process is similar to regular textile product manufacturing. That means from raw materials, products are made through weaving/knitting, dyeing, final inspection, and so on. So we are here to tell you what happens after discarding the used materials. One of the most interesting things is the whole process can be done without using dye or water.

- Discarded materials are collected through recycling programs.

- Many tech-based companies are constantly coming up with new ideas for recycling. Have you ever wondered how plants turn materials into fibers? It’s fascinating to think about! The plants need to decide which idea to fix to transform the material into those strong, versatile fibers we use in so many different ways.

Materials are reduced to fiber using the technology, which is later used in making woven fabrics.

Current scenario of closed-loop in Bangladesh:

Unlike other Asian countries, Bangladesh doesn’t much deal with post-consumer wastage. Talking about why, our readers can find two reasons.

Looking at the first line, we are fond of reusing our garments until there is absolutely nothing. Secondly, as a developing country, we are not dealing much with fast fashion and rapid discarding of clothing yet.

Our main concern is pre-consumer materials which are directly collected from industries. As the production of recycled yarn/fabric is a very price-sensitive business, mills are more interested in exporting that waste rather than processing it. But days are changing. Beximco is working with Recover to uncover this huge workforce in our country.

Did you know that in 2020, the EU and Switzerland alone generated about 7 million tonnes of garment waste? Unfortunately, around 70% of it ended up in landfills and waterways. It ultimately leads to climate change and global warming. So to reduce the wastage problem as well as make a better world, closing the cycle is a must step.

REFERENCE:

2. Scholar

3. Video from Youtube.com

4. Image Source: https://knowledge-hub.circle-economy.com

5. Image Source: https://blog.uniform.com.au

6. Photo by Ron Lach : https://www.pexels.com/photo/woman-on-top-of-heap-of-clothes-8453423/