Finishing is one of the most crucial processes in the textile industry. But it is also infamous because of wasting a lot of water and releasing toxic chemicals. For many years inventors have been working on various eco-friendly finishes. They are not only sustainable but also economical. Textilernd team is presenting you with some of these green finishes.

Plant-Based Finishes:

This type of finish is extracted from plants. They are popular in herbal textiles. Recent research proves to find materials from basil leaves, turmeric, neem, etc.

Water-Based Finishes:

For some time now, water-based polyurethane has been used as a functional finishing. This has a higher tendency of abrasion resistance, elasticity as well as flexibility. It gives the fabric a softer handle. It is waterproof & moisture-permeable, which gives comfort in summer.

Enzyme-Based Finishes:

Microbial enzymes are used for fabric treatments like bio-polishing, de-sizing, and bio-scouring, which require less energy and are more eco-friendly than chemical-based methods. Enzymes replace toxic chemical finish. Various enzymes are used in this process. We find cellulose enzyme in denim, whereas amylase in woven garments finishing.

Recycled Content Finishes:

This finish does two things in one shot. Not only it is a proper use for waste, but also a solution for manufacturers to reduce demand for virgin materials. It has multiple benefits, including adding texture, reinforcement, or aesthetic effects to fabrics.

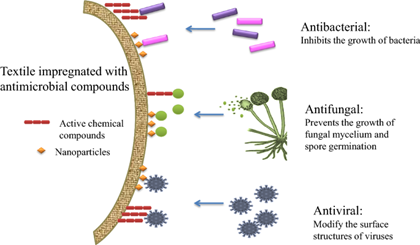

Natural Antimicrobial Treatments:

Chitosen, tea tree oil, or silver ion- they all are anitimicrobial agents. Their main function is to inhibit the growth of bacteria, fungi, and other microbes. They give textiles smoother finishes without any odor.

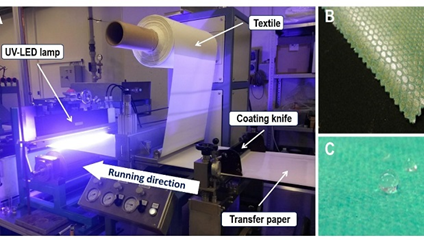

UV-Curable Coatings:

This strong, flexible, chemical-resistant coating is highly used as an adhesive for textile materials. It is the quickest finish in the textile industry. Besides it has several benefits that you can’t ignore. For instance, this coating doesn’t need any solvents or water. Less energy is sufficient. Also, heat-sensitive substrates can be coated safely. This type of coating is done by exposing materials to intense and powerful ultraviolet lamps. Though it is a comparatively new technology, it is already introduced in many industries.

References:

www.ebooks.inflibnet.ac.in/hsp09/chapter/ecofriendly-finishing-with-enzymes

Really valued information in this letter. All we have to use eco friendly chemical why we are using future generations resources. So we have to save this plant to them.

Thanks again.

Wasantha.