What is Fabric Cutting in a apparel industry?

To make a complete garments, cutting is necessary. Cutting means to out the garments pieces from lays of the fabric with the help of templates(markers).Generally the marker is applied (drawn, traced, sprayed, clipped, pinned) to the top ply of a lay.

Objectives of fabric cutting:

The objectives of cutting is to separate fabric parts from the spread of the lay according to the dimension of the marker for the purpose of garments making according to the pattern pieces.

Requirements of fabric cutting:

In order to achieve these objectives, certain requirements must be fulfilled-

- Precision (Exactness) of cut.

- Clean edges.

- Un fused edges.

- Support of the lay.

- Consistent cutting

What are the cutting technique used in apparel factory?

There are mainly three types of cutting technique-

- Completely by manual-Hand operated scissors.

- Manually operated powered knife.

-

-

-

-

- Straight knife.

- Band knife.

- Round knife.

- Die cutter.

- Notcher cutter.

- Drill.

-

-

-

3. Computerized technique.

-

-

-

-

- Knife cutting.

- Cutting by water jet.

- Leaser cutting.

- Plasma torch cutting.

-

-

-

Today we will discuss only on Straight Knife Cutting Machine only.

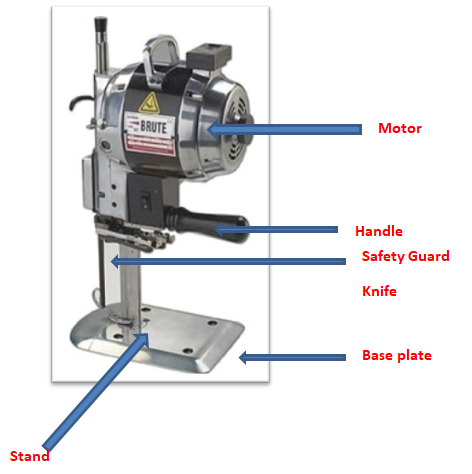

Straight Knife Cutting Machine:

Specification:

Motors: Available with 1 Phase Motor of 110 V and 220 V & with 3 Phase Motor of 220 V and 380 V.

Speed: With Single / Dual speed, Variable speed is not available.

Blades: High Speed Steel is standard blade. Optional blade/s are carbon steel, Teflon coated, wave edges, height:-10-13”, Width- 1.5-3cm, thickness 0.5mm

Belts: Fine, medium, coarse, rough, waterproof are available.

Weight: 34 lbs; 15.4 kgs.

Horsepower: . 65 hp .1 ph & .93 hp .3 ph.

Working principle of Straight knife cutting Machine:

- Firstly, switch on this cutting machine.

- Then, place the cutting machine at any corner of the table.

- Then switch on the blade.

- Then the operator moves the machine by hand through the stationary fabric layers and cut along marker lines until finish the marker.

- The greater the power of the motor , the heavier the machine .

The motor power needed is determined by-

- The height of the lay

- The construction of the fabric.

- The curvature of the line being cut.

- The stroke of the blade

Advantages of Straight knife cutting Machine:

- Comparatively cheap & and can be cut many plies at a time

- Higher lay of height can be cut very easily.

- Round corners can be cut more precisely than even round knife.

- Production speed is very good.

- Garments components can be directly separated from fabric lay.

- Fabric can be cut from any angle.

Disadvantages of Straight knife cutting Machine:

- Sometimes deflecting occur due to the weight of the motor.

- Knife deflection is high in risk, when any height is to high.

- Sometimes accident may happen.

Band Knife Machine :

Features:

- This machine worked as saw mill technique.

- Not possible to cut fabric directly from lay.

- Block pieces of fabric required in bundle form to cut by this machine.

- Blade moving vertically through a flat working table.

- Machine remains stationary and fabric is moveable.

- Specially used to cut small parts more accurately.

Advantages of Band Knife cutting Machine:

- Straight and accurate cutting from the first layer to the bottom layer

- Air blowing table provides air cushion for material easy movement

- Equipped with knife sharpening device, sharpening underneath table

- No metal pieces on table surface

- High accuracy and vertical cutting finish

- Adjustable knife running speed

- Special bearing guide design to keep knife moving in same position

Disadvantages of Band Knife Machine:

- Fabric wastage is high.

- Work load high.

- Push cutting needles in better vision but is more dangerous.