Finishing Section of a Garments/ an Apparel factory:

The finishing department is the department which comes after all the department and it plays an equally important role in the final appearance of the garments. Finishing is an area which is generally overstaffed being the last link of the value chain all the problems from the previous stages have to be sorted out here. This department is located at the 4th floor. Here mainly workers performs pressing, folding and packing of garments. This includes hand stitching (unseen handwork done inside collars and lapels to give them shape) and its automated substitutes. This may also include adding buttons, hooks, eyes or trims as well as clipping loose threads. After completing pressing, the garments are folded with a predetermined area. Garments are folded according to the direction of Buyers requirements or in a standard area.

Responsibilities of Finishing Section in Apparel/ Garments Factory:

The major responsibilities are performed by the finishing department. It is their duty to confirm the required quality as required by the buyers. For this they performed several action which can only be performed after the garments production.

They perform –

- Cut the excess threads

- Check the stitch quality

- Suck out the loose thread sticking with the garments

- Check the shade of different parts of the garments

- Check the accessories

- Trimming

- Attachment of button if required

- Hand sewing if needed

- Check all the labels and their position as instructed by the buyer

- Measure the size according to the size label

- Check faulty areas of the garments

- Remove spots if found

- Pressing if required

- Attaching tags

- Folding as guided by the buyers

- Assortment and packing

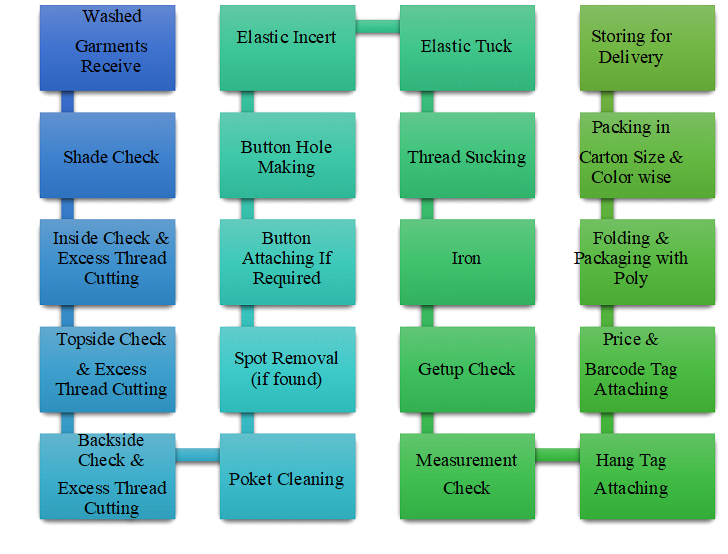

Work Flow of Finishing Section of an Apparel factory :

Below are the general process flow of finishing section of a apparel factory. There might be some changes based on the requirements.

The activities of the finishing department of Apparel factory:

The activities carried out by the finishing department are described shortly below –

Trimming :

This involves the removal of the extra threads form the garment at the stitched area. This operation is done by scissors. Workers stand around the table and cut extra threads form every part of the garments. They works in groups, different groups cut thread of different area of the garments. After cutting of extra thread the lose threads & other impurities are sucked off by a sucker machine.

Buttons Attaching:

All buttons must be in accordance with the relevant fabric performance standard and the care instructions selected for the garment. Each button must be securely attached to garments with at least 16 stitches.

Button-holes :

Stitch density of buttonholes must have full edge cover with no fraying. Cleanly cut buttonholes and trim all threads. Tie off and secure stitches, where using a single thread chain-stitch buttonhole. Worker position buttonholes correctly to prevent unfastening, dragging and gaping.

Snap Button attaching:

Some garments required snap buttons. Garments industry uses manual controlled snap button machine GZN – 2 manual button attaching machine. This process is performed in two stage. At first hole is made and then button is attached. Sometimes metallic logo is attached with this machine.

Thread Sucking :

Loose threads are sucked by the thread sucker. It‟s a vacuum machine which suck out all the loose threads adhering with the garments.

Semi-pressing :

This action is performed before the getup check to ensure that all the parts are joined exactly where it should be and the out looking of the garments is as required by the buyer.

Pressing :

The pressing is done after the garments have been completely inspected and the garments are pressed on the basis of how they will be folded during packing.

Getup Check :

Getup check is must for all the garments. It is the operation to check the visual appearance of the garments. All the buttons, pockets, flap, cuff, collar etc. are matched with the recommended garments getup. If the garments does not pass the getup check, it is sent to the alter section. Shade of all the garments parts are matched in this section

Measurement Check:

All the garments are measured in this section part by part. This has done with the approved measurement sheet for each and every sizes.

Spot Removing :

If any spot is found on garments then it is sent to the spot removing section where workers use

- Thinner jet spray to remove dirt

- Dry spry to remove lubricant

- Denim pen to darken the strips found in denim fabric/garments

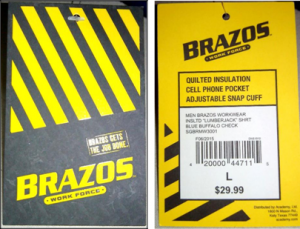

Ticketing and Bar-Coding :

Retailers request that manufacturers supply them with ―hanger ready garments; in other words, the garments must be pre-ticketed with bar-coded price tags attached and hung on the hangers the retailers will use. A contractor or a distribution warehouse routinely handles the ticketing.

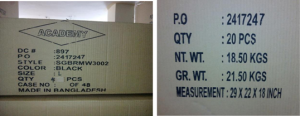

Packing :

At the garments industry packing is done manually according to the packing list. This packing list prepared by the merchandiser according to the requirement of buyer.

Finally the goods are ready for shipped and transferred to the relevant departments for storage and shipping on time.

Ref. :

- Industrial attachment report at “Silver Composite Textile Mills Ltd.” by Mohammad Ali Hayder under supervision of Sazid Elahi, Lecturer, Dept. of Apparel Engineering, Bangladesh University of Textiles.