The vivid hues and intricate patterns we admire in textiles don’t magically appear. Behind the scenes, many chemicals play crucial roles where surfactants are particularly important and versatile behind the scenes- players. Textile wet processing involves procedures aimed at treating fibers, yarns, or fabrics using various chemicals to attain specific attributes like color, texture, and functionality. Due to their surface-active properties, surfactants are widely utilized in these operations. this article explores the significance of surfactants in the wet processing of textiles, examining their roles and influence on the end product.

What is Surfactant?

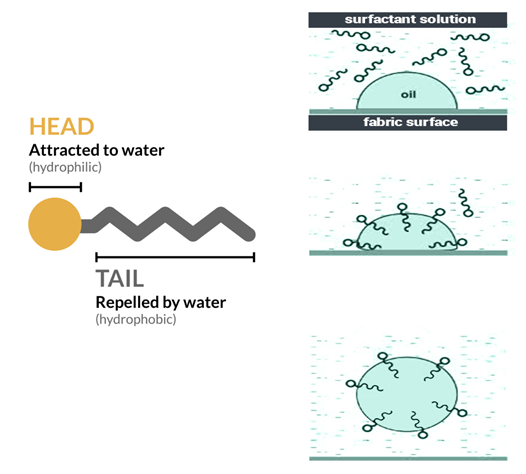

The chemical component which reduces the surface tension of substances thereby increasing the spreading and wetting properties. It comprises both hydrophilic ( water-attracting) and hydrophobic (water-repellency) components. These special properties allow it to interact and change the properties of surfaces and liquid properties.

Key Roles of Surfactants:

- Wetting Agents: Due to the water-repellent properties of fibrous cotton, surfactants reduce the surface tension thus allows to spread evenly across the fabric and facilitate efficient wetting. This is very vital for the subsequent processes such as dyeing, printing, and finishing for the optimal penetration of dyes and other chemicals.

- Dispersing and Emulsifying Agents: Dyes and other finishing agents often act as insoluble solids or oils. In this case, Surfactants act as dispersing agents by breaking down the materials into tiny particles that can be evenly dispersed throughout the processing bath. This results in bright and consistent colors and finishes by ensuring uniform uptake and avoiding clumping.

- Detergents and Scouring Agents: Wax and oil impurities are common in natural fibers. Surfactants act as detergents and remove the impurities, leaving the fibers clean and ready for subsequent processes.

- Leveling and Retarding Agents: As leveling agents, it can regulate how quickly different parts of fiber absorb the dye, producing a uniform, smooth finish. Moreover, as retarding agents surfactants slow down dye uptake for deeper penetration and improved colorfastness.

- Lubricants and Softeners: Fibers and Fabric quality can be impacted by friction during processing. Surfactants act as lubricants, reducing friction and protecting fibers. Additionally, it can soften the fabric, enhancing the drape and feel of the fabric.

- Anti-Static Agents: In the case of synthetic fabrics, static glom can be a problem. It can be lessened by surfactants that improve comfort and easy handling.

Beyond the Basics:

The application of surfactants extends beyond these core functions. Such as:

- Printing: The use of surfactants ensures even transfer of printing inks onto fabric.

- Desizing: It removes the sizing agents that are applied to fibers during weaving preparation.

- Water Repellency: Creating water-resistant finishes by altering the surface properties of fibers.

- Flame Retardancy: Aiding in the uniform application of flame-retardant compounds, thus helping in flame-retardant finishes.

In summary, surfactants play a crucial role in the processing of textiles exhibiting diverse capabilities that enhance fabric quality and processing efficiency. Their proficiency in dispersion, emulsification, detergency, form control and wetting underscores their indispensable role in achieving the required textile properties. As the textile industry continues to evolve, surfactants continue to play a key role in navigating the intricate waters of fabric transformation and process efficiency.

References: