What is Pilling?

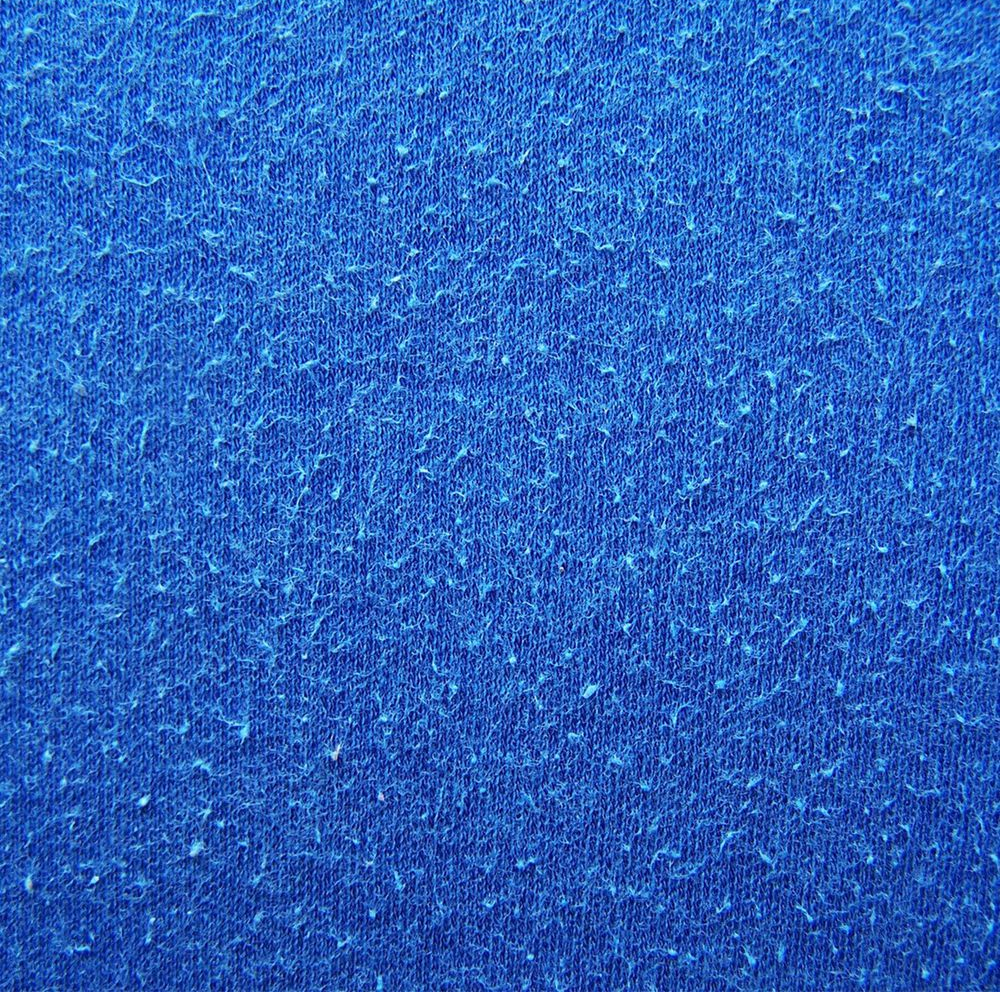

A ‘pill’ or more commonly known as a bobble, fuzz ball, or lint ball is a small ball of fibres that form on the face of a piece of fabric. It is caused by abrasion on the surface and is considered unsightly as it makes fabrics look worn.

Pilling is a surface defect of fabrics caused by wear, and is generally considered an undesirable problems. It happens when washing and wearing of fabrics causes loose fibers to begin to push out from the surface of the cloth and over time, abrasion causes the fibers to develop into small spherical bundles, anchored to the surface of the fabric by protruding fibers that haven’t broken.

What are the Causes of Pilling ?

Loose fibres have a natural tendency to move to the surface of a piece of fabric, where they are subject to friction, this causes the fibres to twist together into small balls. Fibres that are still secured to the fabric are also twisted into the ball, which causes the pill to be secured to the surface of the fabric.

Friction is caused in the normal course of people using the furniture, rubbing against the surface of the fabric. Laundering also causes friction – washing machines agitate fabric, causing the surfaces to rub together.

Pilling is more noticeable on synthetic fibres. This is mainly because natural fabrics shed loose fibres easily and less noticeably, while man-made fibres are extremely strong, so the pills are anchored strongly to the fabric.

Transfer pilling is when the pilling is a different colour to the main base fabric. This occurs when two fabrics have pilled together. Clothing, throw rugs or cushions are normally the cause.

Normally Pilling tests done with below two machines.

- ICI Pilling Box Tester

- Martindale Abrasion and Pilling Tester

ICI Pilling Box Tester :

ICI Pilling Box Tester is used to rapidly replicate pilling on fabrics in a fraction of the time due to normal wear then determine surface pilling and snagging properties of both in woven and knitted fabrics.

ICI Pilling Tester complies with ISO12945-1, BS 5811 etc. ICI pilling tester uses a universal drive system with 2 or 4 position, electronic digital counter, and sample mounting fixture. The machine accepts ICI Pilling boxes and ICI pilling drums.

Specimens are mounted on polyurethane tubes and tumbled randomly under defined conditions in a cork lined box. Pilling is assessed visually after a defined period of tumbling.

Standards for ICI Pilling Box Tester:

GB/T4802.3, ISO 12945.1, BS5811, IWS TM152

Martindale Abrasion and Pilling Tester :

The Martindale Abrasion and Pilling Tester is the standard method of determining the wear resistance of textiles or leather and the resistance to pilling. Samples are rubbed against known abradents at low pressures and in continuously changing directions and the amount of abrasion or pilling is compared against standard parameters. Adaptable to test a wide range of applications including textiles, socks, leather, coated upholstery, carpets, wood and shirt collars.

Standards of Martindale tester:

Abrasion: GB/T 21196.2, GB/T 13775, ISO 12947, ASTM D4966, IWS TM 112, M﹠S P19, Next 18, SN 198529, TWC 112, JIS L1096

Pilling: GB/T 4802.2, ISO12945-2, ASTM D4970, IWS TM 196, M﹠S P17, Next TM26, SN 198525

Ref. :

- https://wikipedia.org

- From the BSC thesis paper of “Study on Quality issues on Woven outer wears” by Mohammad Ali Haydar (ID : 2016-1-4-064), Supervised by Dr. Kaniz Farhana, Bangladesh University of Textiles.

- https://jamesdunloptextiles.com