What Is Garment Printing?

Garment printing can be described as the controlled placing of defined areas of colour on to a garment. Printing is a form of localized dyeing. Printing processes include techniques such as roller printing, screen printing.

There are different types of garment printing techniques. Most of them are described on below. ( For Video training “Click here“)

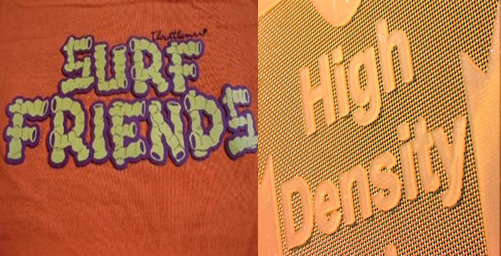

Plastisol Print:

- Good colour opacity onto dark garments and clear graphic detail with, as the name suggests, a more plasticized texture.

- Plastisol inks require heat (approx. 150°C) to cure the print.

- Due to excess phthalate in PVC, this is banned for Children’s wear.

High Density Print:

- This is one of the recent developments in printing which gives thick prints on the surface of garments.

- Achieved by either giving more number of coats or by using thickener indirect films used for making the screens.

Non PVC Print:

- Relatively new breed of ink and printing with the benefits of Plastisol but without the main toxic components – soft feeling print.

- Suitable for kids wear.

Discharge Print:

- Used to print lighter colours onto dark background fabrics, they work by removing the dye already present in the garment.

- This gives a much softer texture

Suedo Ink Print:

- Suede is a milky coloured additive that is added to Plastisol. With suede additive you can make any colour of Plastisol have ‘suede’ feel.

- Generally 50% suede additive to your normal Plastisol.

Pigment Print:

- These penetrate the fabric more than the Plastisol inks and create a much softer feel.

- Also useful for larger area prints where texture is important.

Glitter Print:

- Metallic flakes are suspended in the ink base to create this sparkle effect.

- Usually available in gold or silver but can be mixed to make most colours.

Metallic Print:

- Gives metallic look.

- Similar to glitter, but smaller particles suspended in the ink.

- Smooth in texture when compared to glitter.

Puff Print:

- An additive to Plastisol inks which raises the print off the garment, creating a 3D feel.

- In this method when the paste is printed and dries it look like normal printing garments but once it is cured the prints gets raised from the surface of fabric.

Distressed/ Khadi Print:

- It consists of titanium dioxide with other auxiliaries.

- The important factor in printing of this is right combination of titanium dioxide and proper choice of binder.

Silicone Print:

- To counter inferior wash and weather durability, poor hand feel of some prints like plastisol printing mills tried silicone inks because of their good washing durability, hand feel, elongation properties and environmental friendliness.

Flock Print:

- This process involves printing of glue on the fabric first, applying the fiber flock on the gel printed by keeping the fabric on special table (electro statically charged).

- It requires a little high time for curing than normal prints. 120 seconds at 160C will be sufficient for curing.

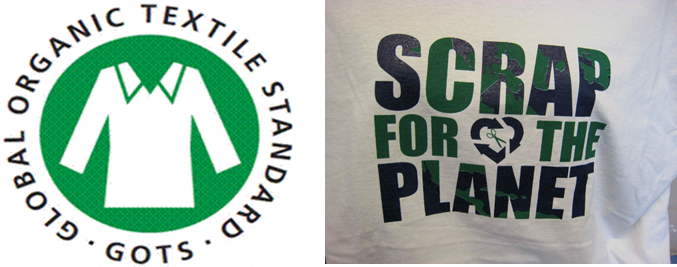

Organic Print:

- Organic print range covers the natural dyes, and the other pigment dyes which lies under the specifications made by GOTS.

- For Printing Organic Dyes the company/ manufacturer should get the certification from GOTS.

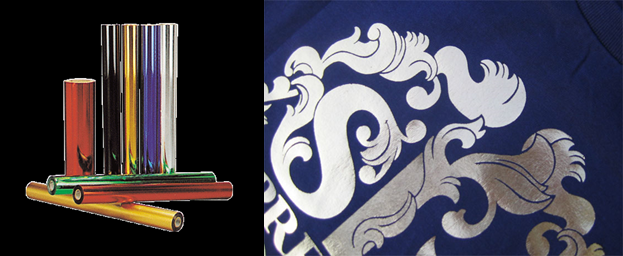

Foil Print:

- This printing method is based on the use of metallic foil paper of aluminum or copper one.

- The print fixation method is similar to transfer printing. This print method is popular amongst youngsters.

Sticker Print:

- This is ready to transfer print.

- The plastisol print is already printed on paper and will be transferred on to garment in the fusing process.

- The main advantage of this method is less expensive.

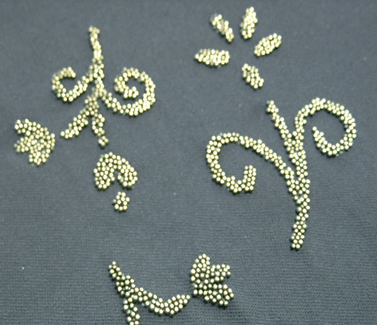

Caviar Bead Print:

- A glue is printed in the shape of the design, to which small plastic beads are then applied.

- works well with solid block areas creating an interesting tactile surface.

Glow in the dark Print:

- Phosphorescent paint is commonly called “glow-in-the-dark” paint. The fluorescent chemicals in fluorescent paint absorb the invisible UV radiation, then emit the energy as longer wavelength visible light of a particular color.

Reflective Print:

- Reflective print reflects any bright light (like headlights). This ink is perfect for anyone looking for high-visibility apparel. Specialty inks and imprint methods are additional features that Custom Ink is able to offer during the design process.

Digital Garment Printing Print:

- DTG printer uses a horizontally moving inkjet print head to apply an image directly onto the surface of a garment, which is mounted on a platen that gradually feeds the garment through the machine directly below the print head. Special, quick-drying inks designed specifically for the fabric being printed

Sublimation Print:

- Sublimation is the process of transferring dye to a fabric using heat. The images and graphics are printed on special paper placed on the garment and heat is applied, allowing the ink to become part of the fabric.

Ref.:

- Internship reports in “THRUPTI DESIGNERS” by Rajesh Kasetty, Siva Jagadish Kumar M, Tejas. Kulkarni