What is Garment Printing?

Garment printing can be described as the controlled placing of defined areas of colour on to a garment. Printing is a form of localized dyeing. Printing processes include techniques such as roller printing, screen printing.

What is Screen Printing?

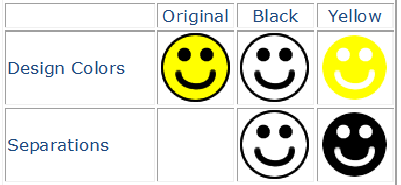

Screen printing is a process, where ink is mechanically applied to a substrate via the use of a screen and squeegee. In its basic form, screen printing is a very simple process. Each colour of the design requires an individual screen so we must separate the design into its component colours. This is done on the computer and each colour separation is printed to a transparent sheet.

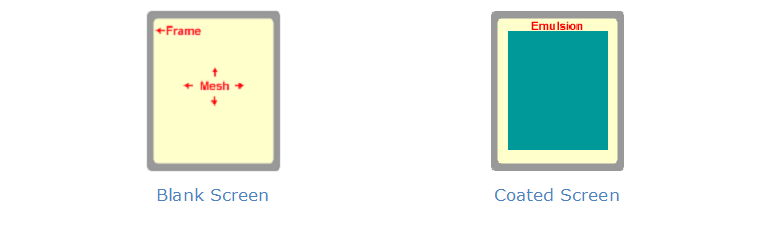

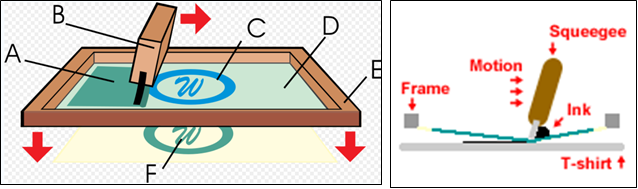

The screen is a rigid frame of wood or aluminium that has a fine monofilament nylon mesh stretched over it. This mesh is then coated with a light sensitive emulsion that will become the stencil through which the ink will pass when printed.

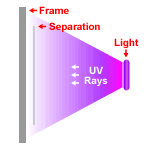

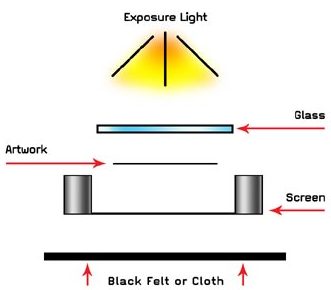

The screen is then mounted, with the separation, in an exposure unit. This machine exposes the screen to high intensity UV light.

Schematic Diagram of Exposing of Screen

When the UV light hits the emulsion a chemical reaction hardens the emulsion making it water and solvent resistant. The separation acts as a shield to block the light in certain areas of the screen. These soft areas are then rinsed away with water to create the open area of the stencil.

The screens are then mounted in the press and registered, or aligned, so that each colour prints in the proper location relative to the other colours. Ink is loaded into the screens and squeegees are installed. The actual printing is accomplished by pushing ink through the screen and onto the shirt with the squeegees. As the squeegee scrapes across the screen it fills the stencil with ink while simultaneously bending the mesh down to transfer the ink to the shirt.

To create the composite image on the shirt, individual colours are printed then the shirt is moved to the next colour. After test prints are run to check alignment, shirts are loaded one by one and printed.

Once all the colours have been applied to the shirt it is removed from the press. The ink on the shirts is still “wet” at this point and needs to be “dried”.

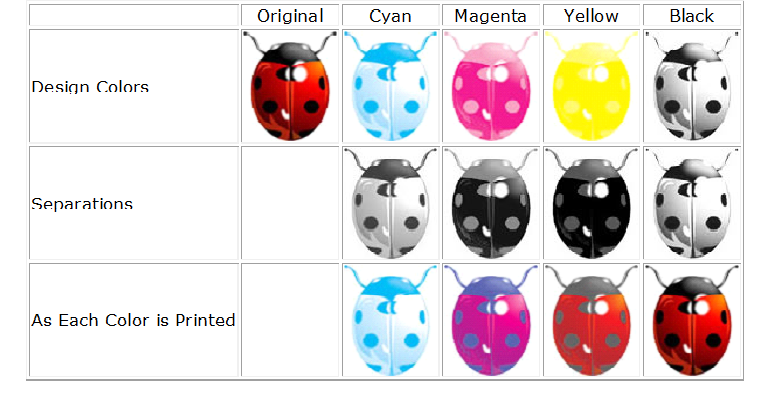

What is CMYK Printing?

4-colour process is a more advanced separation and printing technique that uses 4 colours of transparent ink to produce the colours from the original design. The four colours, Cyan, Magenta, Yellow, and black (CMYK), are printed as halftones that interact with each other and the white background of the shirt to create colour and tonal values. A wide spectrum of colours can be represented but some colours are impossible to produce.

4-color process is used mostly for photographic or digitally created designs because many shades and colors can be created with only four screens. High screen counts and screen frequencies are required to create the tiny halftone dots.

One drawback to 4-color process is that the garment must be white.

What is Mesh Count in Printing ?

The mesh count is the number of threads per inch (tpi) used to weave the mesh. Typical mesh counts for screen printing t-shirts range from 85 tpi to 355 tpi. The mesh count defines basically two things: The thickness of the ink deposit and the size of halftones that can be printed.

The lower mesh counts, 85-110 tpi, have a relatively large thread diameter and more space between the threads (called “open area” ). This allows for a thicker deposit

and more ink to pass through the screen. Typically, lower mesh counts are used for specialty inks (like glitter) and when a thick deposit is needed on dark garments.

The high mesh counts, 305-355 tpi, have a very small thread diameter and less open area. These are used when fine detail and high halftone are needed.

Mesh Count for Different Garment Prints:

- Glitter : 25–60

- Flock adhesive : 45–125

- Puff-up colors : 55–125

- Overprint : 80 –110

- Pigment ink printing areas/lines : 110 –175

- Plastisol : 125–305

- Pigment inks, half-tone : 155–255

- Sublimation transfer : 195–305

Mesh Specifications:

| Mesh count | Thread diameter |

Mesh opening |

Open surface |

Fabric thickness |

Weight | |

| cm mesh/inch | micron | micron | % | micron | g/m2 | |

| 5 | 12 | 500 | 1500 | 56 | 850 | 271 |

| 6 | 16 | 400 | 1267 | 58 | 780 | 208 |

| 7 | 18 | 350 | 1079 | 57 | 675 | 186 |

| 8 | 20 | 350 | 900 | 52 | 685 | 212 |

| 9 | 24 | 250 | 860 | 60 | 455 | 145 |

| 10 | 25 | 300 | 700 | 49 | 576 | 195 |

| 12 | 30 | 250 | 583 | 49 | 470 | 162 |

| 12 | 35 | 300 | 533 | 41 | 585 | 234 |

| 14 | 40 | 300 | 414 | 34 | 595 | 273 |

| 16 | 40 | 200 | 425 | 46 | 370 | 139 |

| 16 | 50 | 250 | 375 | 36 | 485 | 217 |

| 20 | 50 | 150 | 350 | 49 | 375 | 98 |

| 20 | 50 | 200 | 300 | 36 | 385 | 173 |

| 24 | 60 | 150 | 267 | 41 | 285 | 117 |

| 28 | 70 | 120 | 237 | 44 | 215 | 87 |

| 30 | 76 | 120 | 213 | 41 | 225 | 94 |

| 32 | 80 | 100 | 213 | 46 | 165 | 69 |

| 36 | 90 | 100 | 178 | 41 | 178 | 78 |

| 40 | 100 | 100 | 150 | 36 | 190 | 87 |

| 43 | 110 | 80 | 152 | 43 | 135 | 60 |

| 48 | 120 | 80 | 130 | 38 | 145 | 62 |

| 56 | 140 | 60 | 120 | 44 | 85 | 44 |

| 59 | 150 | 60 | 110 | 42 | 98 | 46 |

| 64 | 160 | 60 | 100 | 37 | 105 | 50 |

| 72 | 180 | 50 | 90 | 41 | 82 | 39 |

| 80 | 200 | 50 | 75 | 36 | 90 | 43 |

| 100 | 250 | 40 | 60 | 36 | 65 | 35 |

| 120 | 305 | 40 | 43 | 25 | 70 | 42 |

| 130 | 330 | 40 | 37 | 23 | 75 | 45 |

Ref.:

- Internship reports in “THRUPTI DESIGNERS” by Rajesh Kasetty, Siva Jagadish Kumar M, Tejas. Kulkarni

Pingback: Screen Printing for Garments: Top Choice for Bulk Orders